Transforming Vision into Castings

ETC Strength

Emirates Technology Castings (ETC) is a global steel foundry leader with a 74,000 sqm plant and an annual production capacity of 15,000 tons. Our facility includes 7,500 sqm for secure pattern storage and advanced technologies like robotic manipulators and LINAC X-ray for precise NDT inspections. Using SAP software, we ensure efficient operations and consistent quality. ETC produces a wide range of steel grades, including Carbon Steel, Stainless Steel, Duplex, Super Duplex, Inconel, and Monel.

Material And Capacity

We are renowned in the industry for manufacturing single pieces weighing between 20 kg and 15 MT. Our commitment to achieving optimal client satisfaction drives us to produce products that cater to diverse customer needs worldwide.

With over 32 years of experience, we take pride in delivering more than 15,000 tons of engineered-to-order castings annually. ETC specializes in casting a wide range of steel grades, including Carbon Steel, Low Alloy Steel, Stainless Steel, Duplex, Super Duplex, Inconel, and Monel.

Strategically located in a global logistics hub, we ensure short lead times while adhering to international standards and maintaining uncompromising quality.

Plant 1

20 kg to 800 kg net weight castings

Up to 1.8m x 1.4m x 1.2m

Auto-molding at 6-8 moulds/hour

Diverse material grades available

Alkaline phenolic chemical bonding

Chromite sand for enhanced performance

High precision machining capabilities

High volume output with quick deliveries

Industry approvals and accreditations

Third-party inspection coordination

Capable of handling exotic materials

Plant 2

800 kg to 15 ton net weight castings

Up to 3.3m x 2.7m x 2.4m

Auto-molding at 2 molds/hour

Diverse material grades available

Alkaline phenolic chemical bonding

Chromite sand for superior quality

High precision machining capabilities

Industry approvals and accreditations

Third-party inspection coordination

Capable of handling exotic materials

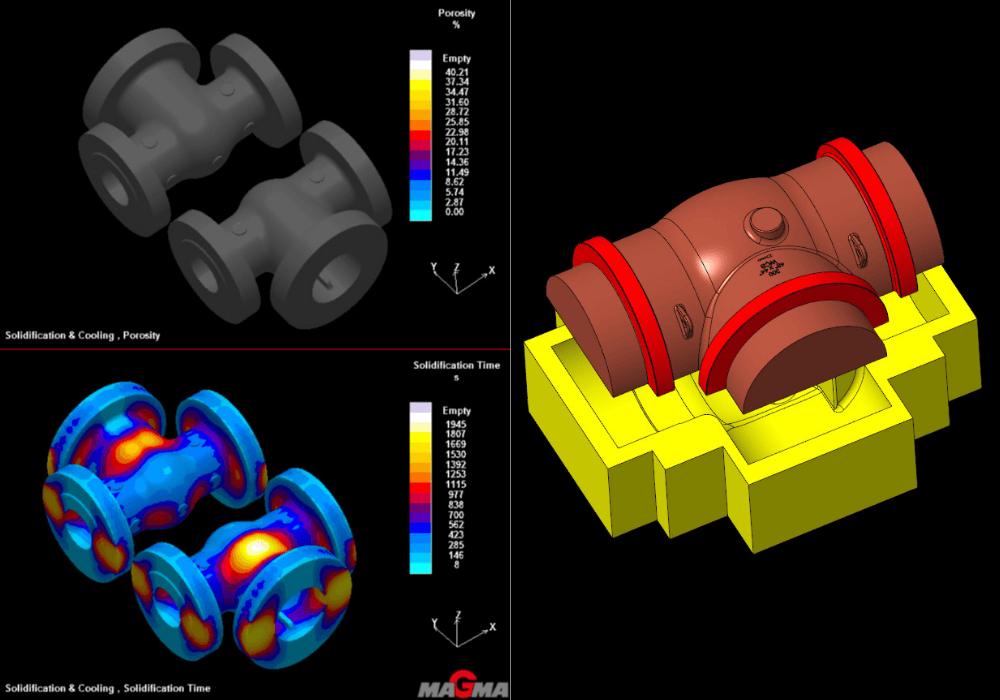

Engineering

We use 3D modeling to manufacture patterns with Creo software, ensuring dimensional accuracy. To produce defect-free castings, MAGMA analysis software is employed to pre-check hotspot areas, porosity, liquid fraction, and solidification time before manufacturing, ensuring the highest quality of castings.

Moulding Line - 1

• 20 KG to 800 KG net weight castings

• Mold size up to 1.8 m X 1.4 m X 1.2 m

• Diverse material grade capabilities

• Auto-molding: 6-8 molds/hour

• Alkaline phenolic chemical bonding process

for molding

Moulding Line - 2

• 800 KG to 15 ton net weight castings

• Mold size up to 3.3 m X 2.7 m X 2.4 m

• Diverse material grade capabilities

• Auto-molding: 2 molds/hour

• Alkaline phenolic chemical bonding

process for molding

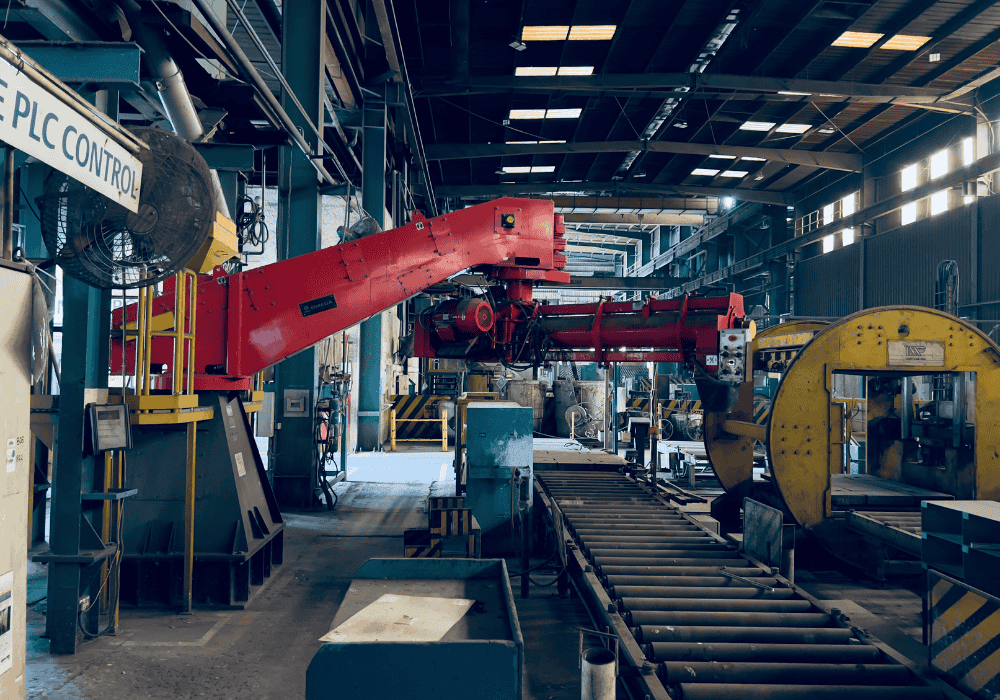

Melting & Furnace Capacity

5 Inductotherm coreless induction furnaces powered by dual track 2250 & 350KW source

Furnace charging manipulator- takes operators away from the high radiant heat source.

AOD/ VD treated Billets for special grades.

Online Gas analysis during Melting.

10,000 Kg Furnace 5,000 Kg Furnace

2,000 Kg Furnace 750 Kg Furnace

500 Kg Furnace

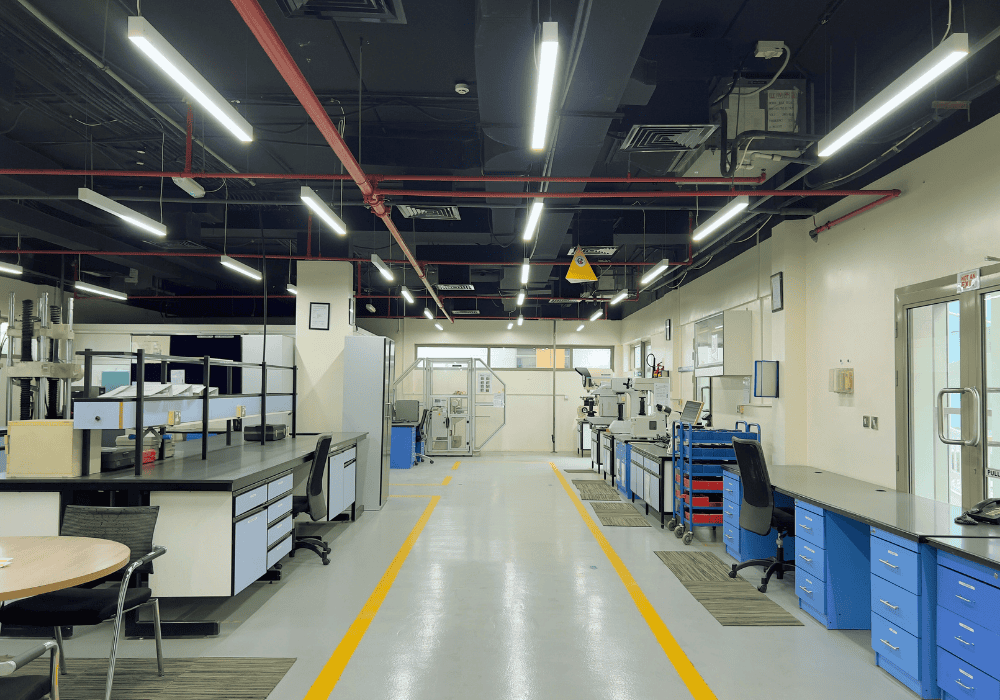

Lab Testing

ETC features advanced metallurgical testing, including high-temperature tensile testing (up to 1,100°C), microstructure and gas content analysis, and mechanical property evaluation. Our lab specializes in testing for hydrogen-induced cracking, sulfide stress corrosion cracking, and sour gas applications. Equipped with gas analyzers for hydrogen, oxygen, and nitrogen, we ensure comprehensive testing to meet diverse industry standards.